|

Fig. 1: Modular Halfcomb Cassette

|

|

The Halfcomb cassette is prefabricated in one piece clear plastic with comb foundation embossed on the bottom. The foundation is beeswax coated.

The box-like cassettes (Fig. 1) are designed to function as modules in modified standard 4 3/4" comb honey supers; they

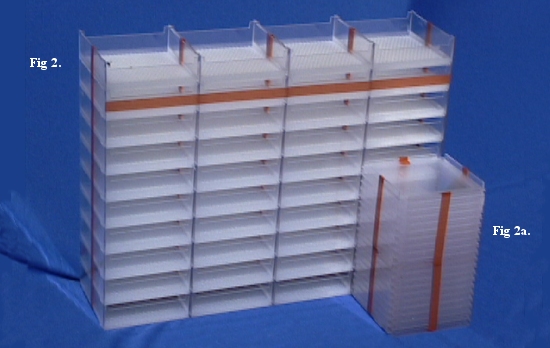

interlock “piggyback”, leaving bee access slots, to form columns of 10 each. Four of these make up the SUPERPACK of 40 cassettes (Fig. 2). The bees build deep-celled honeycomb

(Halfcomb) directly into the cassettes from the bottom upward. The bottom of each cassette then serves to regulate comb depth in the next cassette.

|

|

Fig. 2/2a: SUPERPACK of 40 cassettes and covers

|

|

The only task left to the beekeeper in preparing supers is to insert the SUPERPACK into the Halfcomb super (see Fig. 3), and to secure it with super springs.

The beekeeper never handles the cassettes or its parts individually until after the cassettes are filled with honey and removed from the super to install the covers (Fig. 2a). There are no section frames (or

separators) to handle or clean when loading, unloading or reloading a super, since the SUPERPACK self-supports in the super.

|